SiteZone RCV Smart Loader

Industry concerns have been highlighted by WISH (Waste Industry Safety and Health Forum) and HSE (Health and Safety Executive) about the risks of bin lifts in automatic mode. There is a critical safety gap - no guards or safety devices currently fitted to the rear of RCV’s to prevent incidents from happening. You’re relying on training and safe systems of work which are the least effective control measure under the hierarchy of control.

To address this, we worked in collaboration with FCC Environment to research, develop, and implement a system that reduce the risks associated with using RCV bin lifts in automatic mode, by stopping the bin lift when a loader is detected in the danger zone.

Safety that doesn’t impact your collection times

A recent article from WISH said that HSE (Health and Safety Executive) data revealed more than 500 serious injury accidents had occurred involving Refuse Collection Vehicle (RCV) bin lifts in the previous 10 year period. And that's only what gets reported.

In January 2023 there was a fatality in Coventry where a loader was lifted into the back of the lorry, and crushed, after his coat became entangled in the lifting equipment.

The inquest jury for the fatality described it as a "foreseeable" accident and in delivering their narrative verdict, jurors said evidence showed the vehicle could have been safer.

With RCV Smart Loader we reduce the risk to your loaders when using bin lifts in automatic mode without compromising the operational efficiency on collection rounds.

We stop the bin lift when a loader is detected in the bin danger zone. And due to the speed of behaviour change that the system enforces it doesn't impact the time taken to complete their rounds.

How does RCV Smart Loader work?

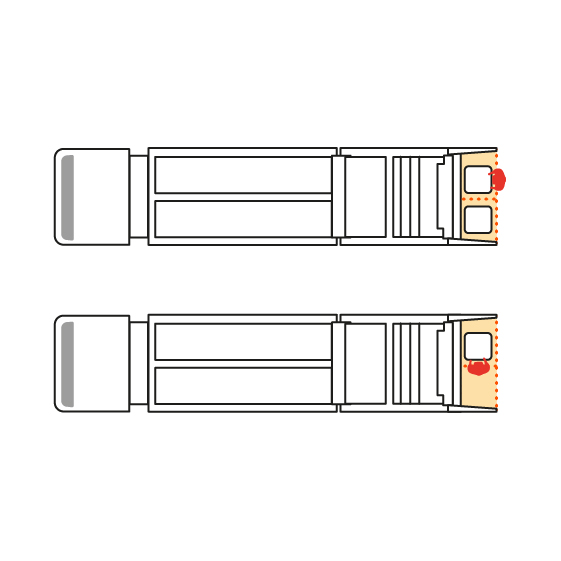

We create a zone around the bin(s) in the bin lift at the rear of the RCV.

All operatives are issued with a tag.

When using automatic mode and the bin is in place the lift will initiate.

If a tag-wearing operative is in the exclusion/bin danger zone:

- The SiteZone system prevents the full lift cycle

- The operative’s tag vibrates

- The driver is alerted via the in-cab display

- A flashing light also warns the operative

After detection there is no need to restart the system, the loader simply reloads the bin correctly staying out of the danger zone.

See RCV Smart Loader in action

"The safety of our employees has and will always remain a priority for FCC Environment. We're pleased to be the first commercial organisation to fully commit to rollout the SiteZone RCV Smart Loader onto our fleet of RCVs. The trials have proven the behavioural change that the system enforces, and this is something we can extend to colleagues on all of our collection rounds."

Steve Longdon

CEO | FCC Environment

75% improvements in behaviour in a single collection round

With the system in use for 2 years on collection rounds it has been well received by loaders, reduced the severity of the risk, and had minimal impact on collections - rounds are completed on time.

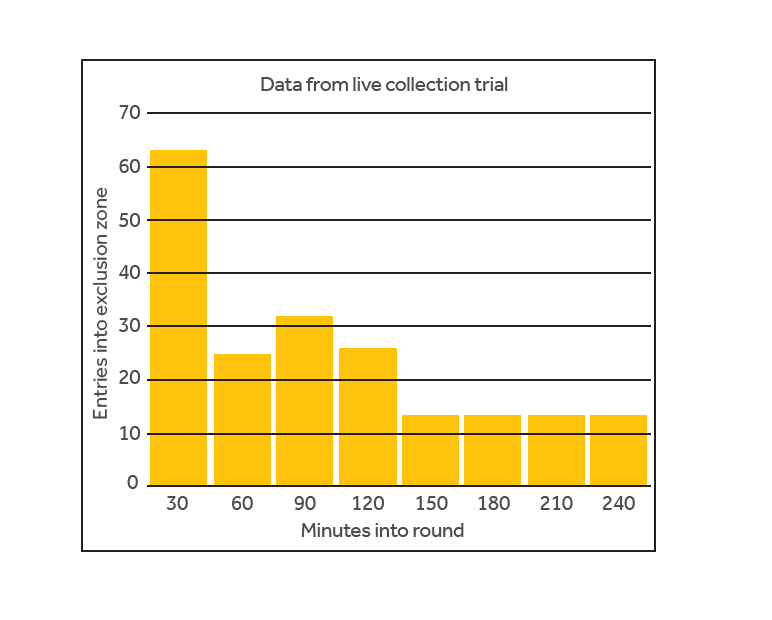

In its first use back in 2023 on a four-hour collection round, we saw significant improvements in behaviour with operators quickly adjusting their distance to the bins during the lift.

After the first 30 minutes there was a 50% reduction in entries to the bin danger zone and throughout the whole round there was a 75% reduction.

And because the system doesn’t impact their loading speed, Loaders say:

"It's hassle free."

"I don't even notice it."

"It makes me feel safer."

Recognised by the industry for its risk reduction

The RCV Smart Loader has been recognised for its risk reduction in the waste and recycling sector. Taking home two risk management awards from the International Institute of Risk & Safety Management (IIRSM) in 2024 and the National Recycling Awards Innovation in Recycling Equipment and Vehicles.

The awards were given in recognition of the collaborative work done by both us and FCC Environment to research, develop, and implement the RCV Smart Loader.

Together, we’ve not only improved safety standards and risk awareness but also set a benchmark for other organisations to follow.

Receiving these awards proves the power of working together to make a difference. And this collaborative approach to fostering a culture of safety and risk awareness was highlighted by the IIRSM judges as contributing to the win.

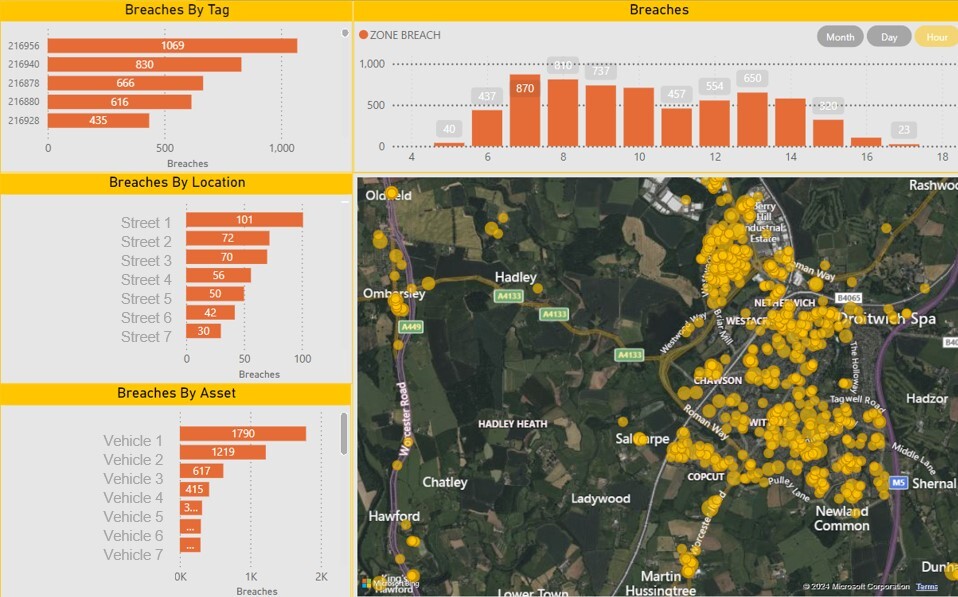

One entry into bin lift danger zone every 11 minutes

The data from our RCV Smart Loader in use on collection rounds for the last two years has shown that a loader enters the bin danger zone every 11 minutes. Tuesdays see more danger zone entries than any other day and 7am is the time of day with most entries into danger zone.

Alongside this you can start to see which roads and which types of collections result in more entries into the bin danger zone.

This information helps you to plan routes, organise shift patterns, and ensure loaders are correctly trained.

Related Articles

Data, data everywhere

Sam BoshierApr 28, 2025 7:00:00 AM

With this year’s theme for World Day for Safety and Health at Work being on the role of AI and digitalisation at work, it got me thinking about data...

Why should we pay attention to near misses?

Gary EscottJan 16, 2025 9:45:20 AM

With our RCV Smart Loader System and Proximity Warning Systems for mobile plant, we collect data about breaches into the danger/exclusion zone. A...

Recognised for innovation at MRW National Recycling Awards

Sam BoshierNov 27, 2024 9:30:00 AM

At a glittering celebration of the sector in London last night, SiteZone Safety and partners FCC Environment took a top prize at the National...